Purchasing Scooter Wheels

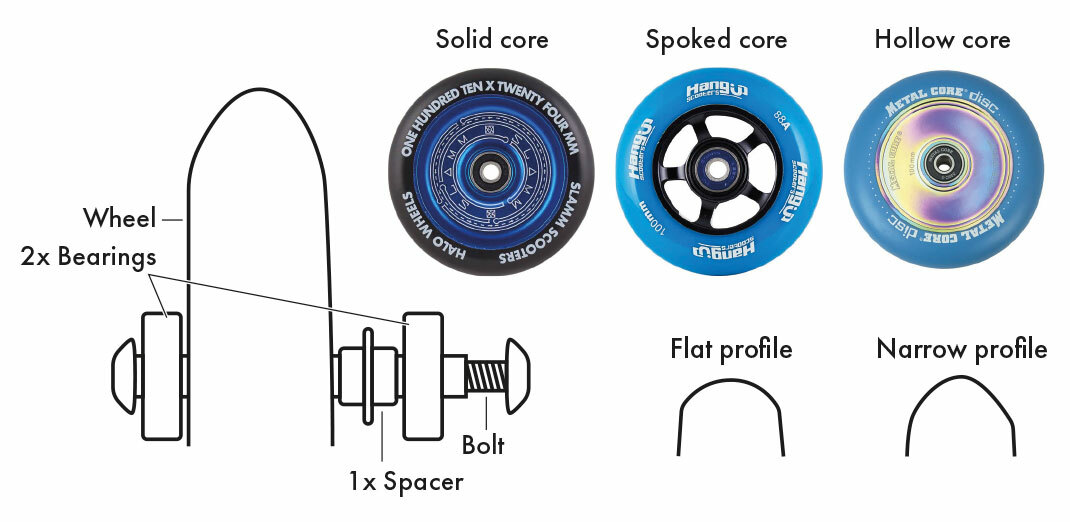

Each wheel requires two bearings and one spacer to operate properly.

Wheels consist of varying materials, sizes, hardness levels, profiles, and distinct cores.

The illustration provides clarity on these components.

Cores

- Solid core. A robust design intended for prolonged durability.

- Spoked core. Features gaps and cutouts. Results in a lighter wheel but is less strong!

- Hollow core. Lightweight interior that retains strength (not as durable as a solid core).

- Plastic core, not illustrated. These do not endure long and exhibit some flexibility.

- Honeycomb core, not illustrated. Follows the hollow core principle but is even lighter due to perforated holes.

Profiles

- Flat profile (provides rubber reinforcement and optimum grip)

- Narrow profile (designed for speed)

Hardness

- The durometer scale ranges from 0-100a, where 100a is the hardest. Most scooter wheels are around 85a.

- Hard wheels are more durable, somewhat slipperier, and faster!

- Soft wheels degrade more quickly but offer excellent grip, ideal for indoor areas and parks.

- Not all manufacturers specify wheel hardness; therefore, experimentation may be necessary.

Installing Bearings into Wheels

- Inserting bearings can be challenging; we provide a video tutorial for installing bearings in a scooter wheel with a metal core here.

Advice

- Ensure bearings are precisely aligned with the centre at all times; misalignment can damage both the bearings and wheel centre.

- Using a hammer on the wheel or bearings during installation will invalidate the warranty and nullify any claims.

- Wheels with a flat profile may not fit in forks designed for a pointed profile.

- Replace worn wheels promptly for safety reasons and to avoid damaging the Flex fender brake!

Claim or Wear and Tear?

Wheels crafted for performing tricks often encounter high stress and naturally, like all wheels, have limited longevity.

Executing spinning tricks such as tail whips or 360s repeatedly applies side pressure on the wheels, which may lead to material breakage or tears over time.

How do you determine if it qualifies for a claim or if wear resulted from usage?

Flat Spots

Hard braking that locks the wheel against the tarmac can produce "flat spots." This abnormality creates a linear indentation in the curve of the wheel, causing an uneven ride.

A "flat spot" is not a manufacturing defect and does not fall under the usual warranty. It arises from incorrect use, as no wheel can be harder than asphalt.

Dehub

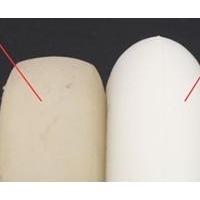

Below is an image of two wheels. The left wheel shows less than 30% wear and appears relatively new, while the right wheel is completely new.

If a wheel appears to have less than 30% wear but the urethane has clearly come apart from the hub, there could be a manufacturing issue, as depicted:

A wheel showing over 40% wear, with the urethane damaged yet still attached to the hub, typically indicates usage wear rather than a production flaw.

If a manufacturing defect is suspected, refer to our claim guide for steps on how to initiate a claim.

Return to Assembling a Custom Trick Scooter

Return to Stunt Scooters Explained here.