Bearings Purchase Guide

Feeling uncertain about which bearings to choose? In this guide, we’ll clarify the most crucial terms and key points regarding bearings. We’ll also discuss which bearings are optimal for your specific riding or skating style.

1. General Information on Bearings

Two bearings are necessary for a wheel to rotate on the axle. The type of bearing can greatly affect the speed and overall sensation of your riding or skating.

No matter what bearing type you own, it’s important to keep away from sand, water, and damp conditions, as these will greatly decrease the longevity of your bearings. Regular cleaning and lubrication can prolong their durability and performance. See how to clean your bearings here.

A spacer is also needed to bridge the gap between the bearings, preventing damage and ensuring smooth rotation when the axles are secured. The size of the spacer corresponds with the axle size.

8 mm spacer

6 mm spacer

Bearings' quality hinges on several factors, including:

- Material

- Precision (ABEC)

- Lubrication

- Sealed or open (Removable Shield)

Choosing the Right Bearing for Your Use:

- If your riding/skating is predominantly outdoors, we suggest sealed bearings with grease lubrication,

as these are highly resistant to dirt and dust, requiring minimal maintenance. - If your activities are chiefly indoors, you might opt for open bearings that are swift and easy to maintain.

- If speed and long-distance travel appeal to you, high-precision bearings with oil lubrication are recommended. They spin remarkably fast and are easy to clean, but dirt can quickly compromise them.

2. Installation

Bearing installation is typically achievable with thumbs. Once the bearing is properly seated, it aligns with the wheel core/hub. Should it protrude at any point, it isn't correctly installed and will suffer damage if used. With a metal core wheel, bearing installation can be challenging; in such cases, utilise a rubber hammer or square wood piece to gently position the bearing.

Never utilise a metal hammer as it will ruin the bearings and void your warranty.

Alternatively, some lubrication can aid in fitting the bearing, but ensure to remove any excess lubricant afterwards.

3. Detailed Information on Bearings

Material

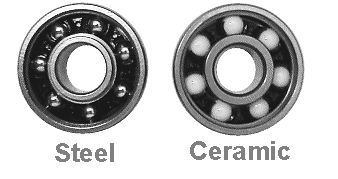

The bearing material is a pivotal factor in dictating their quality and lifespan. Most bearings are constructed from steel. Economical options typically use pressed sheet metal or hardened carbon steel, both of which aren’t advisable for longevity.

Superior bearings utilise bearing-specific metals such as chrome, titanium, or Swiss steel.

In ceramic bearings (commonly used in speed skating), the balls comprise industrial ceramic (Silicon Nitride). These ceramic balls are less prone to rust and outlast steel.

Price and quality are closely linked when considering bearings, and reliance on recognised brands is generally a sound choice for acquiring durable and quality bearings.

Precision/ABEC

Industry-accepted ABEC specifications categorise bearings. ABEC evaluates how effectively bearings transfer applied force. Higher ABEC classifications offer superior precision, efficiency, and speed potential, though this does NOT imply faster spin. The ABEC rating doesn't account for factors like spacer accuracy and wheel material. After usage, all bearings do experience a decline in precision.

Note that not all brands adhere to the ABEC rating (e.g., Bones), and other scales for bearing assessments are in use.

ABEC denotes Annular Bearing Engineering Committee.

Lubrication

Bearings utilise either oil or grease for lubrication. A bearing should never operate without lubrication; lacking it risks melting, speed loss, or complete blockage.

- Oil: Offers high speed due to reduced resistance in lubrication; thinner oils enhance speed but demand more frequent upkeep.

- Grease: Offers superior resistance to water and dirt compared to oil. Nearly maintenance-free but results in greater resistance, thus reducing speed.

Notice: Water can strip off all lubrication! Should this occur and the water evaporates, the bearings may overheat, melt, and produce noise upon subsequent use, necessitating replacement. In rare cases, provided they haven't been used after drying, cleaning and oiling might salvage them before the next use.

Shields/Seals

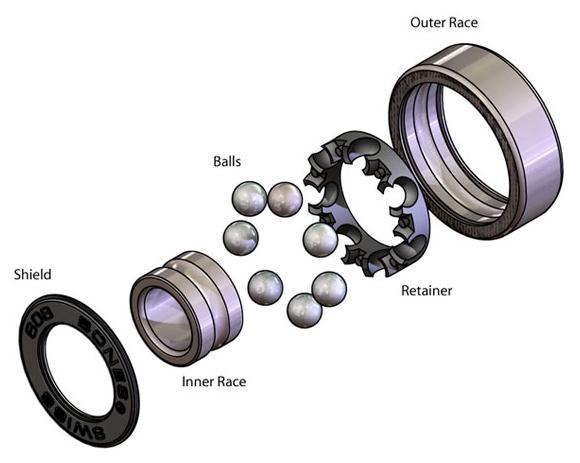

To shield bearings from dirt, sand, and water, a shield or seal is typically installed on one or both sides of the bearing.

- A Shield is generally a metal barrier affixed to the outer ring with slight clearance to the inner ring (aka dustproof bearing). Bearings equipped with shields have low friction, promoting smoother rotation and higher speed. However, these are not entirely impervious to water and dirt.

- A Seal (shown below) comprises steel-reinforced rubber attached to the outer ring, lightly touching the inner ring. It provides superior protection and minimal upkeep requirement but incurs higher friction and a slightly reduced speed.

4. Understanding Standards and Bearing Precision

The ABEC grades account for multiple factors, including the track’s eccentricity (roundness) in the inner ring. The table below illustrates maximum permitted eccentricity.

| Type | mm | Inches |

| ABEC 1 | 0.0075 mm | (0.000295") |

| ABEC 3 | 0.0050 mm | (0.000197") |

| ABEC 5 | 0.0035 mm | (0.000138") |

| ABEC 7 | 0.0025 mm | (0.000098") |

| ABEC 9 | 0.0012 mm | (0.000047") |

This implies that a higher ABEC classification entails less deviation in bearing parts, enabling more efficient power transfer to the wheel.

ABEC and ILQ aren’t directly comparable, as ILQ is a brand, whereas ABEC is a standard.

ABEC bearings gauge manufacturing precision, excluding durability or load-bearing function. Twincam, the creator of ILQ, ranks their bearings akin to the ABEC scale. Despite that, ILQ bearings feature 6 balls, whereas ABEC bearings include 7.

To differentiate, ILQ is not a standard like ABEC bearings. Consequently, ILQ should be considered an unrated bearing from a specialist inline bearing producer, unsuitable for industrial machinery.

Bones bearings are solely crafted for skating—comparison with ABEC standards is not applicable.

Below is the terminology for bearings and their shields (bearing markings usually include the type and size, e.g., 608ZZ).

608

- Standard bearing

- 22 mm outer diameter

- 7 mm width

- 8 mm inside diameter

688

- Mini/Micro bearing

- 16 mm outer diameter

- 5 mm width

- 8 mm inside diameter

Z

- Shield, 1 metal shield

- Open on the reverse side for uncomplicated maintenance (always orient the open side towards the wheel's interior when installing)

ZZ

- Shield, 2 metal shields

- Shields are affixed with a small C-ring, removable for maintenance.

2RS/RS/RZ

- Seal, 2 steel-reinforced rubber seals

- Seals affixed without C-rings; extraction for maintenance possible using a needle.

BRS

- Seal, 2 steel-reinforced rubber seals (contact-free)

- Seals mounted without C-rings. Provides excellent water ingress prevention.