Guide to Cleaning and Lubricating Bearings

Regularly maintaining your bearings by cleaning and lubricating them is essential to ensure they function at their best. This practice enhances both the lifespan and the performance speed of your bearings.

Important: Avoid contact with water & sand

Exposure to damp and filthy conditions can greatly reduce a bearing's lifespan.

Instructions for Cleaning and Lubricating Bearings on Skates, Skateboards and Scooters

Step 1

Tools needed: A cleansing agent like a grease-dissolving fluid, such as Fluid wash, a waterproof container, a pin or box cutter, a small brush, and fresh oil/grease.

Detach the bearings from the wheel. You can refer to the YouTube video above for guidance on removing bearings from a wheel. Though the demonstration is shown on a skate, the same procedure applies to skateboards and scooters.

Take off the wheels and remove the bearings.

Step 2

Utilise the brush to rid the outer parts of the bearings from any grime.

Bearings fall into two categories: open and closed. Open bearings are easier to service, but closed ones require cautious removal of the shield for maintenance.

Ensure the exterior parts of the bearings are cleaned.

Step 3

For sealed bearings, you may remove the seal with a pin.

Certain closed bearings with metal shields are held by a small C-clip. Before removing the shield, detach this C-clip with the pin.

Remember to clean the seals and C-clips if available.

A drawing pin or box cutter is used to detach seals (without a C-clip) from the bearing.

Step 4

Submerge the bearings in a sealed container with the cleaning agent, then shake it for several minutes to eliminate any accumulated dirt.

Initially, clean the bearings with a small brush, then proceed with cleansing agent.

Step 5

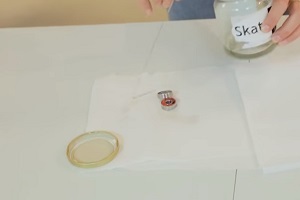

Extract the bearings from the container and spin them to remove any remaining cleansing agent. Alternatively, an air compressor can be used to blow out the fluid. Place the cleaned bearings on a clean cloth or kitchen tissue.

Bearings have been taken out of the container holding a cleansing agent.

Step 6

Assess whether the cleaning was effective. Gently spin the bearing while holding its inner ring. If it doesn't spin smoothly or makes a grinding noise, the bearing hasn’t been cleaned sufficiently. If this occurs, repeat the cleaning with a new batch of agent. Heavily soiled bearings may need this process repeated 2-3 times.

Verify the thoroughness of the cleaning by spinning the bearing as shown.

Step 7

Place the bearings onto a clean cloth or tissue again. They are now prepared for lubrication. Apply 1-2 drops of oil (too much will attract dust) or 3 mm of grease evenly around the bearing.

Ensure the oil or grease is spread properly by spinning the bearings, which can be efficiently done using a drill machine.

Carefully apply 1-2 drops of oil into the bearing.

Step 8

Reattach the shields onto the bearings and insert the bearings back into the wheels of the skate, skateboard or stunt scooter.

Seals are reinstated on the cleansed and lubricated bearings, and then bearings are put back onto the wheels.

Post-Cleaning and Lubrication

Once bearings are cleaned and lubricated, it may take a few miles for the oil or grease to fully disperse within, and thus for the bearings to operate at their peak.